AI-solutions

We are bring state of the art AI solutions that make your business grow and be more profitable

Capabilities

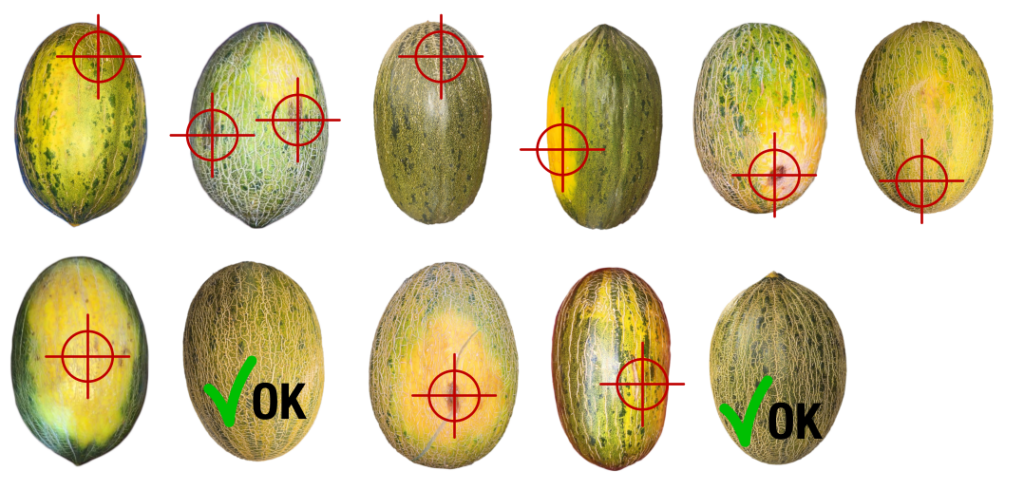

- Inspecting defects on the surface of fruit

- Determining the color of fruit

- Determining the shape of fruit

- Measuring the size of fruit

- Measuring the weight of fruit

AI Grading and Sorting

Optical Fruit Grading and Sorting Machine

Discover the future of fruit quality inspection with our pioneering machine vision technology for agriculture. Specializing in external quality assessment of fruits, Berstron´s technology stands out for its particular expertise with citrus fruits such as oranges and tangerines. Our innovative system employs the latest artificial intelligence advancements and high-resolution imaging to deliver precision and efficiency.

As a leading provider of electronic fruit and vegetable calibrators in Brazil’s agriculture tech market, we’re changing the way farmers, wholesalers, and retail industries approach quality control. Our system uses eight high-speed, high-resolution cameras to conduct a thorough surface analysis, inspecting approximately 96% of each fruit’s exterior.

Not only limited to fruits, but our technology is also expanding to include the calibration of flowers, with a particular emphasis on roses. It’s a versatile solution for various agricultural and horticultural needs.

Our calibrators are robustly built and designed to handle fruits gently. They feature stainless steel design and improved feeding systems, making us a top choice for those seeking a melon calibrator. This top-tier equipment combines weight and external quality selection, setting a new standard in the industry.

Given the comprehensive inspection, we recommend using a 250mm cup instead of the standard 200mm, facilitating improved visibility around the peduncle and the flower. This alteration does mean a slight decrease in speed, from 5 to 4 fruits per second, but the trade-off is a more detailed quality assessment.

Given the remarkable advancements of our machine vision technology in agriculture, we recommend that you integrate our system into your quality control process. You’ll not only gain a precise tool for inspection but also achieve significant cost savings due to improved efficiency. Please note that our lead time for manufacturing is approximately 3 months.

What types of produce can we grade

We are specialised in citrus fruits and melons but our systems are perfectly capable to grade a wide variety of fresh produce like:

Oranges, Lemons, Limes, Pears, Peaches, Plums,

Kiwis, Tomatoes, Grapes, Strawberries, Blueberries,

Cherries, Apricots, Mangoes, apples and many more.

This is what the machine is seeing at 100% speed

Oranges

Lemon

Tomato

What are the Commercial and Practical Advantages of our AI driven solotions?

Efficiency:

Computer vision can automate the process of sorting and grading, making it faster and more efficient than manual labor.

Consistency:

Unlike human graders, computer vision systems can provide consistent results, unaffected by fatigue or subjective judgment.

Cost-effectiveness:

Although the initial investment may be high, in the long run, automation can lead to significant cost savings by reducing labor costs and increasing productivity.

Quality Improvement:

By accurately identifying and sorting out low-quality produce, the overall quality of the output can be improved, leading to higher market value and consumer satisfaction.

Scalability:

Computer vision systems can be scaled up to handle larger volumes of produce, making them suitable for large-scale industrial applications.

How does an AI Vision system work?

1. Image Acquisition:

This is the first step where a camera or a set of cameras capture images of the object, in this case, fruits or vegetables. It’s similar to taking a photograph.

2. Image Processing:

Once the image is captured, the system needs to understand what’s in the image. It does this by analyzing the image and identifying different features such as color, size, shape, and any visible defects. This process involves various techniques like segmentation (dividing the image into parts), and feature extraction (identifying key characteristics).

3. Classification:

After the features are extracted, the system classifies the object based on these features. For instance, it might classify fruits as ‘good’ or ‘bad’ based on their color and whether they have any spots or not. This classification is done using pre-set rules or algorithms.

4. Decision Making:

Based on the classification, the system makes a decision, this decision could be about sorting the fruits or vegetables into different categories based on their quality.

5. Machine Learning:

Berstron´s advanced vision systems use machine learning, a type of artificial intelligence, to improve their performance over time. They learn from previous classifications and decisions, and adjust their algorithms to make fewer mistakes in the future.

In essence, a vision system is a combination of hardware (like cameras) and software (algorithms and machine learning) that mimics the human vision process to identify, classify, and make decisions about objects.

Research Report about AI integration

In the research report, Artificial Intelligence (AI), specifically in the form of computer vision, plays a crucial role in the quality evaluation of fruits and vegetables. Here’s how:

Automated Sorting and Grading: AI algorithms are used to automate the process of sorting and grading fruits and vegetables. This replaces the traditional manual process which can be inconsistent, time-consuming, and subjective.

Feature Extraction: AI, through computer vision, is used to extract key features of fruits and vegetables such as color, texture, size, shape, and defects. These features are then used to evaluate the quality of the produce.

Classification: AI algorithms are used to classify fruits and vegetables based on the extracted features. This classification can help in determining the quality of the produce and its suitability for the market or for further processing.

Comparison and Evaluation: The research report also uses AI to compare and critically evaluate different algorithms proposed by researchers for quality inspection of fruits and vegetables. This helps in identifying the most effective methods for quality evaluation.

In summary, AI, through computer vision and machine learning algorithms, plays a central role in automating and enhancing the process of quality evaluation of fruits and vegetables.

Some Q&A

A smart fruit grading system is needed because manual sorting and grading can be inconsistent, time-consuming, variable, subjective, onerous, expensive, and easily influenced by the surroundings.

The costs of Optical grading systems vary greatly depending on complexity and capacity of the desired system. In general these systems provide a great ROI (Return On Investment). We would love to get in contact with you and investigate the best solution for your business and draft a proposal tailor made for your situation.

Various methods used in computer vision for sorting and grading fruits and vegetables include preprocessing, segmentation, feature extraction, and classification. These methods address fruit and vegetable quality based on color, texture, size, shape, and defects.

Computer vision can automate the process of sorting and grading, making it faster and more efficient than manual labor. It can provide consistent results, reduce labor costs, improve the overall quality of the output, and can be scaled up to handle larger volumes of produce.

he grading system for fruits and vegetables is a standard that categorizes produce based on factors like size, shape, color, and quality. It helps in determining the market value of the produce and ensures consistency in quality for consumers.

Grading levels for fruits can vary by country and type of fruit, but common grades include “U.S. Extra Fancy,” “U.S. Fancy,” “U.S. No. 1,” and “U.S. No. 2.” These grades are based on factors like size, color, firmness, and the absence of defects.

Grading refers to categorizing fruits or vegetables based on their quality characteristics like size, shape, color, and absence of defects. Sorting, on the other hand, is the process of separating the produce based on specific criteria, which could be their grade, size, or type.

Grading systems can be manual, where humans inspect the produce, or automated, where machines use computer vision and other technologies to grade the produce. Automated systems can be more consistent and efficient.

Grading is the process of categorizing products based on specific criteria to ensure consistency in quality. In the context of fruits and vegetables, grading can be based on factors like size, shape, color, and absence of defects.

The three methods of grading could refer to manual grading (done by humans), mechanical grading (done by machines), and computerized grading (done by machines using computer vision and other technologies).

Leave us a note and we will keep you informed!

Share it if you like it!

Berstron is a company dedicated to the manufacture, development, sale and maintenance of fruit and vegetable machinery (especially in the citrus sector).

JET BOX S.L.

C/ Dos de Mayo, 71 Entlo

12550 Almassora

Castellón – España