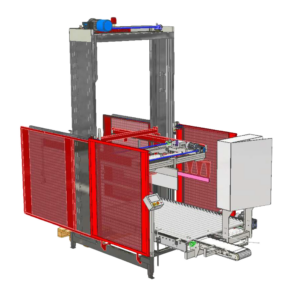

Palletizers

We are committed to you!

With over 1000 units operational in various industries we can confidently say we have fine-tuned our systems from back to front. We have implemented all our customers wishes in the latest version. Now providing a selection of highly desired add-ons that further increase efficiency and functionality of our palletizer machine.

We strive to provide the best ROI and reliability over time.

Our goal is to enhance your productivity and profitability by providing you with efficient, adaptable, and sturdy solutions. We prioritize useful functionality over aesthetics without overlooking the finer details, and focus on creating solutions that are tailored to your business needs. Our engineers and mechanics are dedicated to deliver solutions that prioritize safety, reliability, and productivity, ensuring that you get the most value for your investment.

We provide a ROI calculator, hit the button below if you want to know how you can streamline your operation while saving money!

Efficiency & Durability

Efficiency is found in all aspects of the design approach as we use industry standard and widely available components which ensures our machines are easily serviceable and maintainable with a minimum of proprietary

components.

Safety

Safety is not an accessory. Safety has been integrated into every aspect of palletizer design to meet all industry standards. Berstron Palletizers come with a comprehensive set of sensors and physical barriers to ensure operator safety. Personal safety while using our palletizers is our highest priority.

Flexibility

Our new modular Add-On options allow you to configure the palletizer exactly to your needs an Electric Box Rotator, Electric Feeder, Passive Feeder and even a Mover to allow flexible placement of you trusted and valued machine.

Add-On options

Box turner

This accessory turns your box clock and counter clock wise to ensure proper label visibility on your stacked pallet.

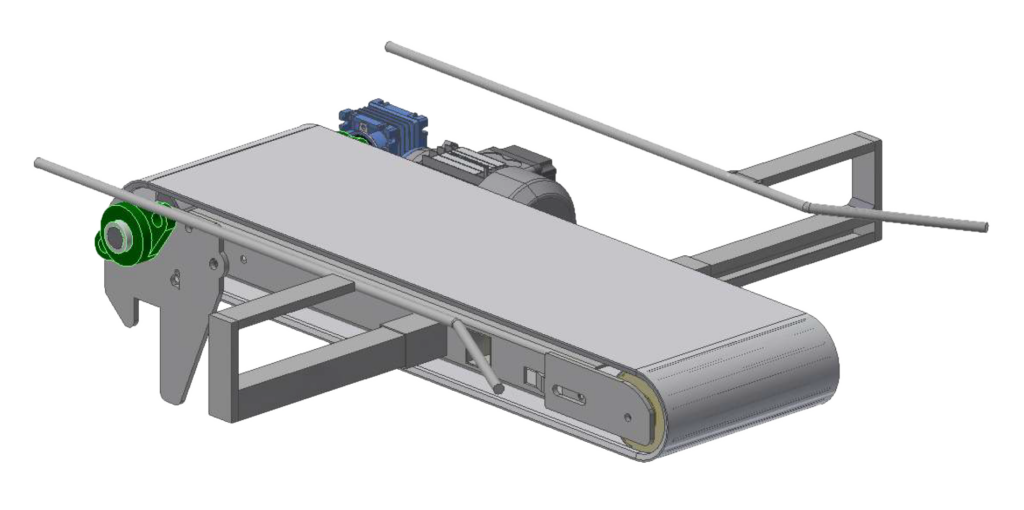

Electric infeed belt

For automatic infeed of boxes at the right speed, providing optimal box separation and production efficiency.

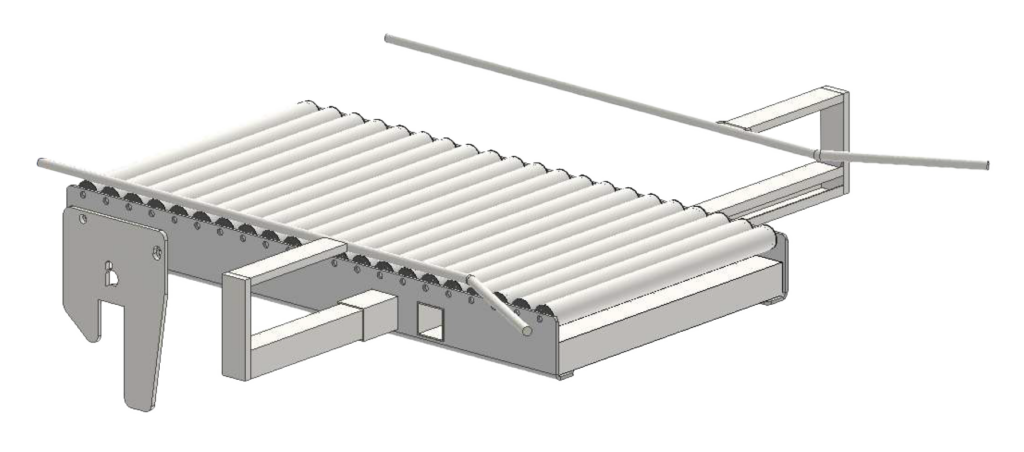

Passive infeed roller

Basic attachment for manual feeding boxes into the palletizer.

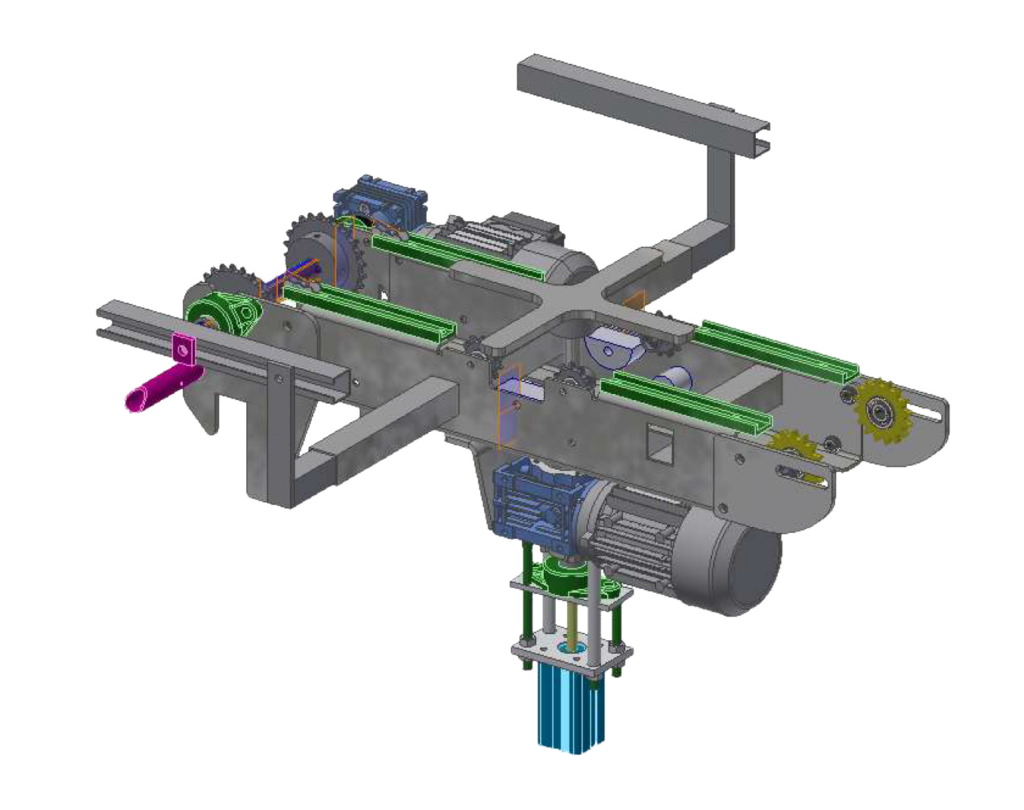

Palletizer mover/mobilizer

This rig can be permanently attached to the palletizer and allows you to easily move it around your production area.

Capabilities & Specifications

Speed layes per minute 1-3 depending on layer layout

Infeed Height: 58-73 cm

Minimum Box/Case Height: 4 cm

Standard Layer Weight: 130 KG

Gripper span: 77-120 cm

Max stack hight: 300 cm

Max Pallet Size: 120 X 100 cm

Operating Interface: 7” Touch screen

Power consumption: 2 Kw

Power connection: 400V, 3 phase, Nul, earth

Compressed Air Usage: 600 Liter per hour

Compressed Air: 6 Bar

Pricing

Starting at €15.800 (download our detailed 2023 pricing PDF below.

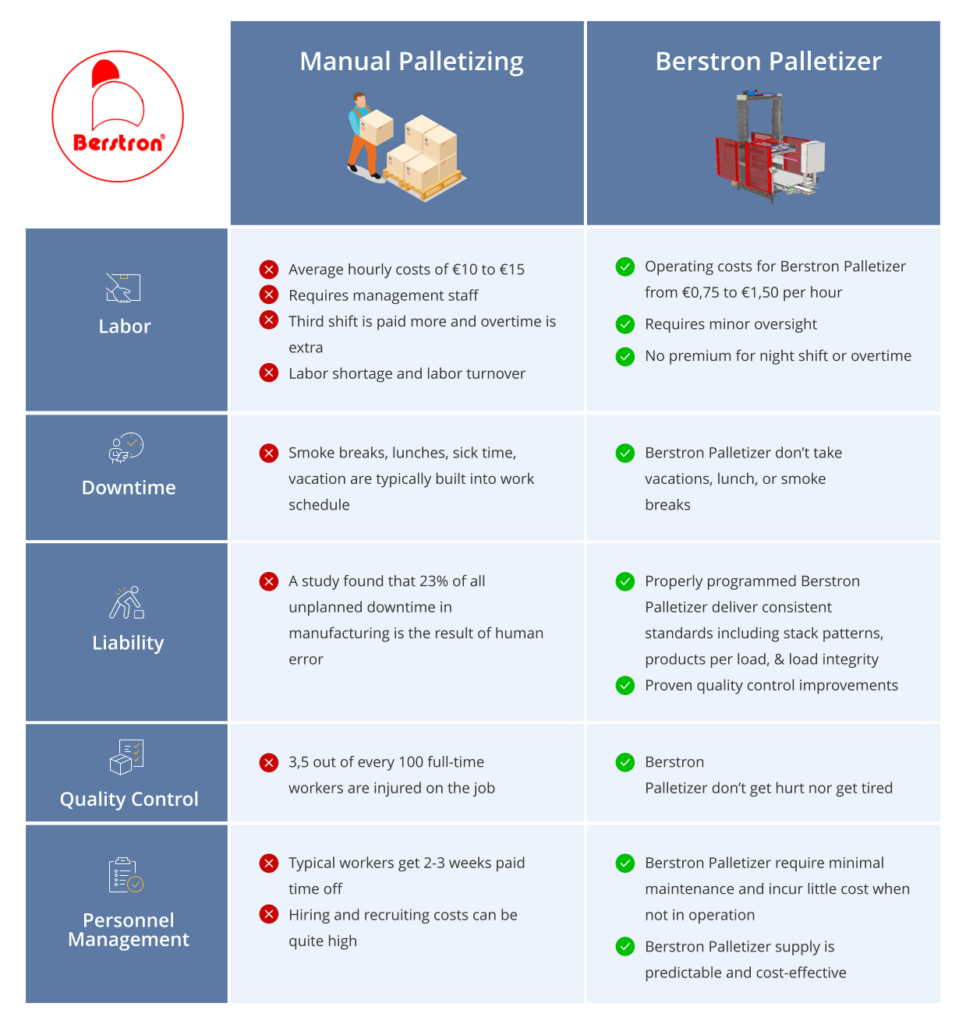

THE HIDDEN COSTS OF NOT DEPLOYING

BERSTRON’S PALLETIZERS

Contact us

Berstron is a company that provides palletizer machines for various industries. They offer highly efficient and adaptable solutions that prioritize safety, reliability, and productivity. Their palletizers come with a comprehensive set of sensors and physical barriers to ensure operator safety. They also offer modular add-ons that allow customers to configure the palletizer exactly to their needs. The company uses industry-standard and widely available components to ensure their machines are easily serviceable and maintainable. Berstron Palletizers’ machines have a speed of 1-3 layers per minute, with a maximum stack height of 300 cm and a maximum pallet size of 120 X 100 cm.

Berstron is a company dedicated to the manufacture, development, sale and maintenance of fruit and vegetable machinery (especially in the citrus sector).

JET BOX S.L.

C/ Dos de Mayo, 71 Entlo

12550 Almassora

Castellón – España