MIN-MAX

Packaging Scales

Innovation mixed with decades of experience provides ingenius solutions

MIN-MAX Packaging Scales

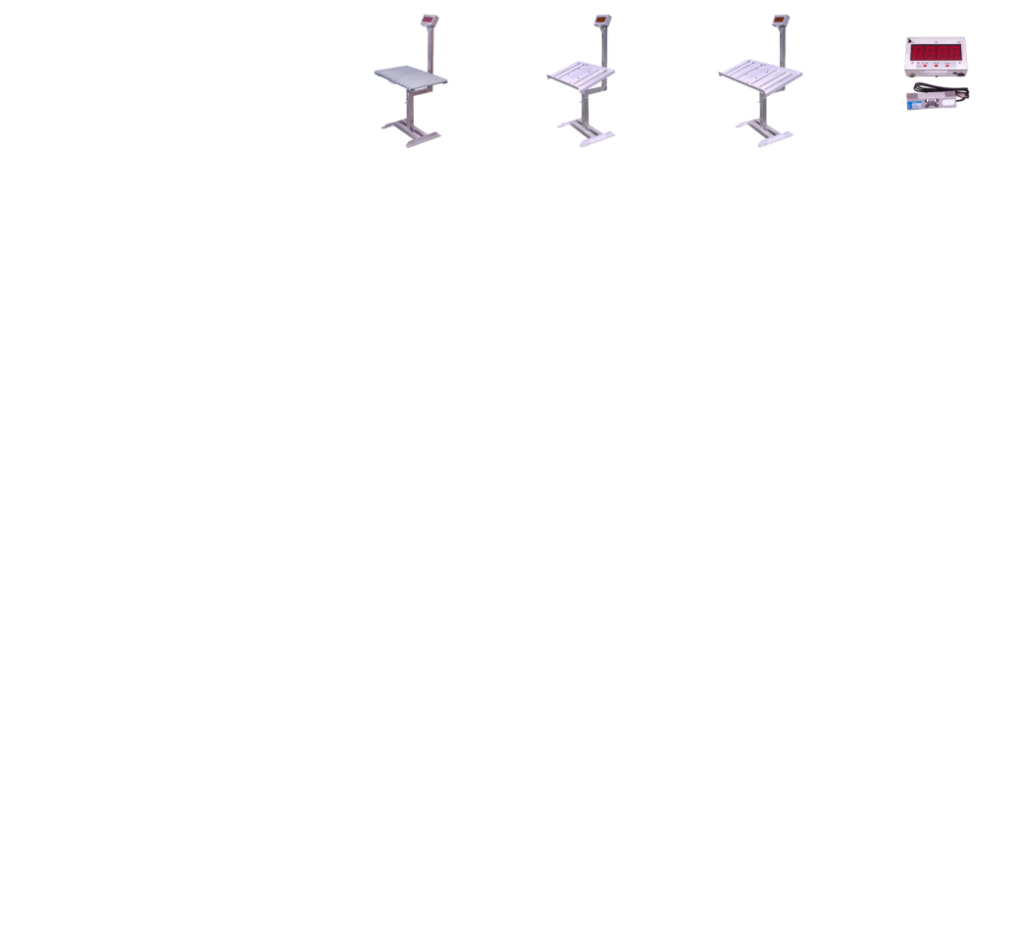

MIN-MAX Crate Version

Accurate and quick measurement for packaging lines

This perticular scale is designed and developed to weigh the content of manually filled containers. You will be able to set a minimum weight and a maximun weight according to you specific use case.

For the operator No light will indicate ¨continue filling¨ a green light indicates ¨weight is within specifications¨ and a red light indicates an overfilling situation.

You can set 9 different weighing scenarios in the memory of the machine. For example one scenario for weighing a basket of strawberries and one more for weighing a basket of apples and so on.

The use of an indicator light instead of just displaying the weight in numbers proves to be more efficient and less straining on the operator. Less weighing errors occur and the speed of the filling process increases.

General Specifications

Plate version

The 40*58 cm (height and angular adjustable) plate angle provides good access for filling larger containers

Plate XL Version

The 40*68 cm (height and angular adjustable) plate angle provides good access for filling larger containers

Roller Version

Ideal to fit within your conveyor system, sturdy and height adjustable between 60cm and 88cm. The roller surface measures 40cm x 67cm.

Head & Sensor KIT

To accommodate those who want to build their own platform we supply the “Head & Sensor Kit” Weighing capacity from 1 to 60Kg

MIN-MAX Table Version

This specialized scale provides precise and speedy measurements for packaging lines. It’s engineered to determine the weight of manually filled containers, allowing you to establish a weight range based on your specific needs.

The operator is guided by a simple light system: no light signifies the need for more filling, a green light indicates the weight is within the set parameters, and a red light warns of an overfill situation.

The machine’s memory can store up to nine distinct weighing scenarios. For instance, you can have one setting for weighing a basket of strawberries and another for a basket of apples, among others.

The implementation of an indicator light system, as opposed to merely displaying numerical weight, enhances efficiency and reduces strain on the operator. This results in fewer weighing errors and a faster filling process.

Specifications

Description

Battery powered industrial scale designed for use at packaging lines

Dimensions: 46mm x 216mm x 180mm

Weight: 795Gr

Weighing tolerances: +/- 1 Gr

Max and min weights: 50Gr to 9.99 Kg

Battery life and Charging time: 3 days, 1 hour charge time

Programmable features: 9 weighing scenarios

Maintanance features: calibration

temperature ranges: 10-40 Degrees Celcius

Warranty: 1 year limited warranty

Product Flyer ENG

Contact us

Berstron is a company dedicated to the manufacture, development, sale and maintenance of fruit and vegetable machinery (especially in the citrus sector).

JET BOX S.L.

C/ Dos de Mayo, 71 Entlo

12550 Almassora

Castellón – España