Visual Sorting

Electronics For Fruit Graders

Simplicity In Installation And Use.

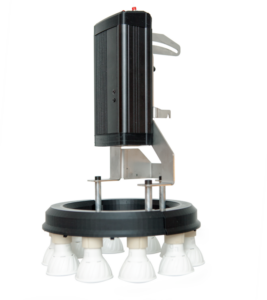

System fully developed by Berstron with simplicity in mind and facilitating the user’s work. The SmartFruit camera module, includes support and LED lighting, all integrated, is installed on a 60mm square tube, without the need for screws. The SmartFruit cameras are already focused, place on the tube, connect to the switch and work.

Robust Technology.

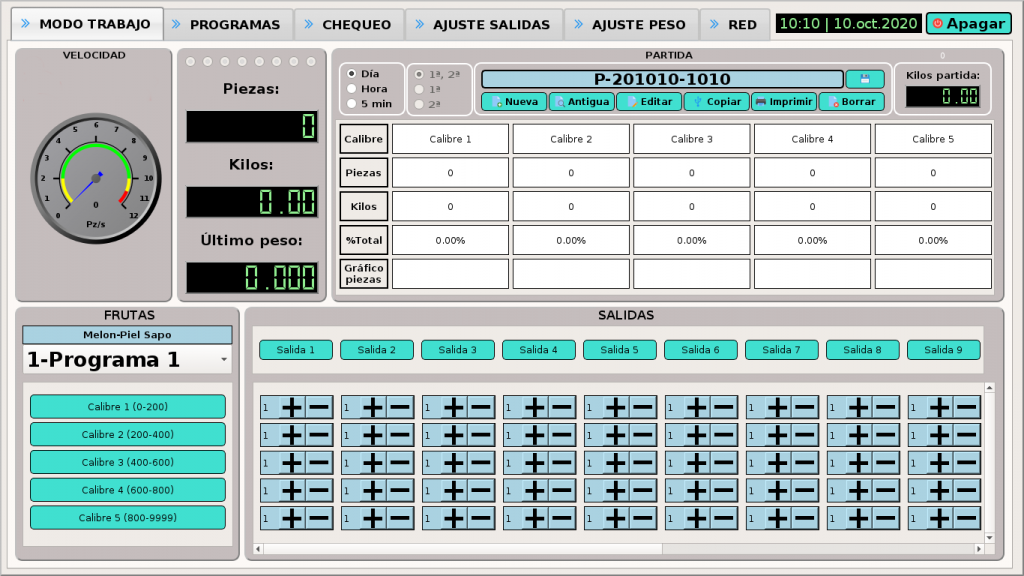

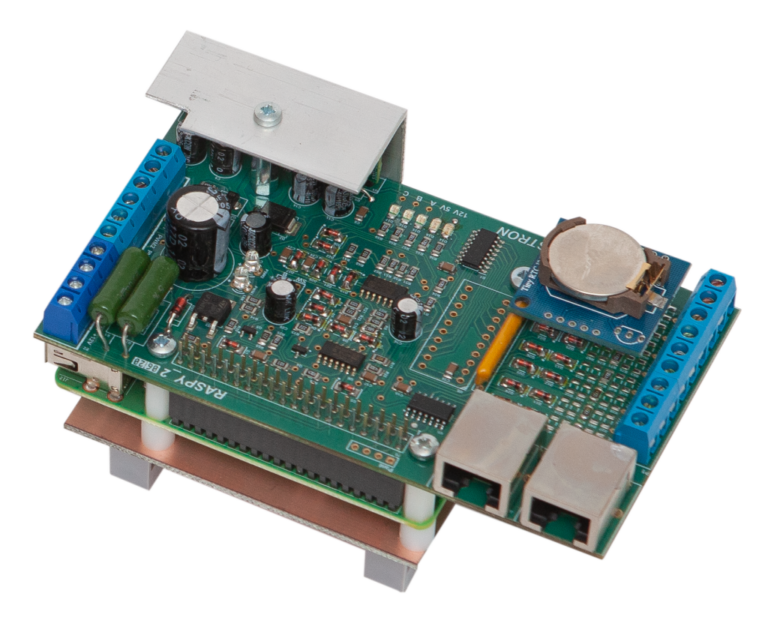

The Smartfruit camera uses an industrial GigE camera with the latest CMOS sensor technology. This sensor offers high capture speed and high resolution with excellent image quality. The image processing unit is made up of a quad-core ARM CPU, which provides high computing power with low consumption on a small board.

High Performance.

High performance evaluating weight, size and color. Our system unites efficiency, quality and innovation in the best value for money system on the market.

Highly Scalable.

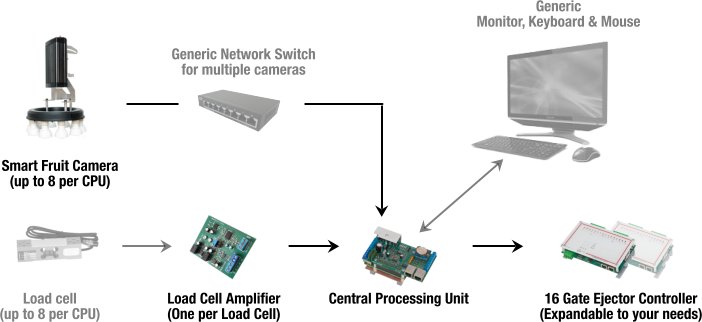

The vision system works with intelligent cameras, the processing of the images of each line is not centralized in a large computer, but is distributed in the intelligent cameras, this makes the system much more reliable and capable of incremental growth. The ejector cards can be installed along the calibrator, connecting to each other, forming a serial bus, this makes the wiring more scalable.

This is what the machine is seeing at 100% speed

Oranges

Scanning for size

Lemon

Scanning for size

Tomato

Scanning for size & color

Technical characteristics

The lowest cost system on the market.

Calibrated by weight, size and color.

Speed up to 20 fruits per second in vision mode.

Speed up to 12 fruits per second in weight mode.

GigE digital camera with high capture speed and excellent image quality.

LED lighting system with support for the SmartFruit camera, it is mounted on a 60mm tube. Assembly does not require screws. The SmartFruit camera is already focused for mounting at a height of 60cm. Assemble and work!.

System totally developed by Berstron.

Possibility of remote control of the system.

Easy-to-use work environment, graphical interface for 24″ FullHD monitors.

What is included?

Host made up of a computer, its own communication card with the ejector cards and its own card to control the signals of the load cells.

Ejector cards, each card can act on 16 outputs.

Weight cards, for weighted calibrators.

SmartFruit cameras for vision gauges.

Camera mounts and LED lights for vision gauges.

Berstron Sorting Solution Overview

Optical Quality Inspection

Our camera systems are also used for incoming produce inspection, an important and effective tool to measure supplied produce at the processing facility.

Quality control of incoming fruit for the citrus fruit industry With Berstron´s optical scanner and the proprietary software solutions you have the ultimate tool to quickly, consistently and reliably run your quality control program.

The Importance of Visual Sorting in Industry and Manufacturing

Visual sorting is a critical component of the manufacturing and production process, and it plays a vital role in ensuring that the final product is of high quality and free of defects. This process involves the use of specialized equipment and techniques to visually inspect and sort items, such as parts, components, or finished products, based on specific criteria.

There are several key benefits to implementing visual sorting in your production process, including increased efficiency, improved product quality, and reduced costs.

Improved Efficiency

Visual sorting allows for faster and more efficient inspection of products, as it eliminates the need for manual inspection and sorting. With the use of specialized equipment, visual sorting can quickly and accurately sort items based on specific criteria, such as size, shape, color, or texture. This not only speeds up the production process, but it also reduces the risk of human error, ensuring that only high-quality products are manufactured.

Improved Product Quality

Visual sorting helps to improve the quality of the final product by identifying and removing any defects or inconsistencies before they reach the consumer. This helps to ensure that the final product meets the required specifications and is free of any defects or imperfections.

Reduced Costs

By improving the efficiency of the production process and reducing the number of defects in the final product, visual sorting can significantly reduce costs for manufacturers. This can be achieved by reducing the amount of time and resources required to manually inspect and sort products, as well as reducing the risk of having to scrap or rework subpar products

Conclusion

In conclusion, the implementation of visual sorting in the manufacturing and production process provides numerous benefits, including improved efficiency, product quality, and cost savings. With the use of specialized equipment and techniques, manufacturers can ensure that their final products are of the highest quality and free of defects. By investing in visual sorting, manufacturers can improve their production processes and stay ahead of their competition.

Berstron is a company dedicated to the manufacture, development, sale and maintenance of fruit and vegetable machinery (especially in the citrus sector).

JET BOX S.L.

C/ Dos de Mayo, 71 Entlo

12550 Almassora

Castellón – España